SAMPLE MOUNTING

Key:

* On NG-6 FCS, the beam center can be varied by up to 50mm (1.97"). Similar adjustments can be made on other instruments, but special arraingements are required.

** Describes the device mounting surface, NOT the appropriate sample holder, e.g. CCR sample holders normally have clearance slots that mate with the specified tapped holes.

** Describes the device mounting surface, NOT the appropriate sample holder, e.g. CCR sample holders normally have clearance slots that mate with the specified tapped holes.

Poster Summary of Sample Mounting Hardware,

Special CCR Sample Mounting,

Powder Aluminum Can Drawings,

Single Crystal Aluminum Can Drawings,

Copper Can Drawings,

Spreadsheet of Cans and Lids Dimensions,

Adjustable Copper single crystal holder for Dil Fridge neutron experiments.

--> Caution: Some instruments (DCS & HFBS) have unique equipment that have different measurements than the standard equipment. <--

<== Select a Class of Equipment from the menu on the left to jump to its Mounting Information.

| Device Closed Cycle Refrigerators |

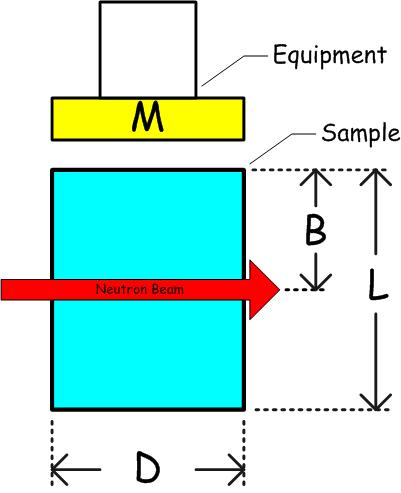

D max. diameter mm (inches) |

B distance to beam* mm (inches) |

L max. length mm (inches) |

M mounting surface description** |

|---|---|---|---|---|

| DCS-CCR (low and high temp.) (standard CCR w/diff. outer cans) |

71 (2.8) | See DCS User Guide | See DCS User Guide | 4-bolt circle 1.75 inch diameter #10-32 tapped

|

| CCR (low and high temp.) | 71 (2.8) | 44 (1.75) | 86 (3.4) | 4-bolt circle 1.75 inch diameter #10-32 tapped

|

| TLCCR-Long | 57 (2.25) | 45(1.75) ± 38; 1400 (55.14) from top |

146 (5.75) | 5/16"-18 stud; 3/8" long |

| TLCCR-Short | 57 (2.25) | 45(1.75 )± 38; 943 (37.14) from top |

146 (5.75) | 5/16"-18 stud; 3/8" long |

| TLCCR-DCS | 57 (2.25) | 68 (2.66) ± 38; 1424 (56.05) from top |

178 (7) | 5/16"-18 stud; 3/8" long |

| TLCCR-HFBS | 57 (2.25) | 45(1.75) ± 38; 1400 (55.14) from top |

118 (4.65) | 5/16"-18 stud; 3/8" long |

| Room Temperature Mount (Normally used for aligning a sample) |

N/A | 44 (1.75) UP from mounting surface |

N/A | 4-bolt circle 1.75" diameter #10-32 tapped (Same as above except inverted) (e.g. mounting surface is under sample) |

| Device Liquid Helium Cryostats |

D max. diamter mm (inches) |

B distance to beam* mm (inches) |

L max. length mm (inches) |

M mounting surface description** |

| OC-DCS (square tail base) | 69 (2.72) | 1375 (54.13) from top | 140 (5.51) | 5/16"-18 stud 3/8" long |

| OC-DCS-2 (round tail base) | 69 (2.72) | 1360 (53.54) from top | 140 (5.51) | 5/16"-18 stud 3/8" long |

| OC-HFBS | 45 (1.77) | 1304 (51.3) from top + 4 mm O-ring |

160 (6.3) | 5/16"-18 stud 3/8" long |

| OC-50 | 49 (1.93) | 942 (37.09) from top + 4 mm O-ring |

128 (5.05) | 5/16"-18 stud 3/8" long

|

| OC-70 | 69 (2.72) | 942 (37.09) from top | 150 (5.9) | 5/16"-18 stud 3/8" long |

| OC-100 | 99 (3.90) | 1192 (46.93) from top | 192 (7.56) | 5/16"-18 stud 3/8" long |

| MACS 50mm OC (Polarized n Beam) | 49 (1.93) | 1306 mm (flange to beam center) + 4 mm O-ring |

1386 mm (flange to bottom of well) | stick has 5/16"-18 stud 3/8" long use with ICE dil fridge or with Oxford dil fridge insert |

| OC-SANS | 69 (2.72) | 930 (36.614) from top | 140 (5.51) | 5/16"-18 stud 3/8" long |

| ICE OC (50mm) | 49 (1.93) | 1305 mm (flange to beam center) + 4 mm O-ring |

102(4) 1372 mm (flange to bottom of well) | stick has 5/16"-18 stud 3/8" long use with ICE dil fridge or with Oxford dil fridge insert |

| Oxford dil fridge with ICE OC | 35 (1.38) | 56(2.20) for ICE OC, 72(2.83) for 10T Lemon | 105(4.13) | 5-16"/18 threaded hole,1/2" deep |

| ICE dil fridge | 35 (1.38) | 55(2.16) | 90(3.54) | M6 threaded hole,4mm deep (without adapter) or 5/16"-18 threaded hole,5mm deep (with adapter) |

| 3He "Big Blue", SD-55 | 81 (3.2) | 38 (1.5) | 152 (6) | 4-bolt circle 1.75 inch diameter #10-32 tapped |

| 3He Dipper with 7T magnet | 70 (2.8) | 44 (1.75) | 88 (3.45) | 1.5" diameter copper plate with a 5/16"-18 threaded hole 1/4" deep |

| 3He Dipper with 70 mm OC | 57 (2.25) | 38-76 (1.5-3) | 102 (4) | 2.125" diameter copper plate with a 5/16"-18 threaded hole 1/4" deep |

| Device Furnaces |

D max. diamter mm (inches) |

B distance to beam* mm (inches) |

L max. length mm (inches) |

M mounting surface description** |

| CTG Furnace | 71 (2.8) | 44 (1.75) | 86 (3.4) | 4-bolt circle 1.75 inch diameter #10-32 tapped |

| BNL-Air/Vac furnace | 84 (3.313) | 25.4 (1.0) | 95.25 (3.75) | NOTE: bottom mount (below the beam) 4-bolt circle 1.75" diameter #10-32 tapped |

| HFBS 1400 C Furnace | 45 (1.77) | 1304 (51.3) from top | 160 (6.3) | M8 stud 7 mm long |

| 1600 C General Use Furnace | 42 (1.65) | 409 (16.1) from top | 100 (3.9) | M8 stud 7 mm long |

| Device Superconductiong Magnets |

D max. diamter mm (inches) |

B distance to beam* mm (inches) |

L max. length mm (inches) |

M mounting surface description** |

| 7T SCM with TL-CCR insert | 47 (1.85) | 44 (1.75) 1753 (69.2) from well top |

1795 (70.67) from well top | 5/16"-18 stud 3/8" long |

| 7T SCM with CT insert | 71 (2.8) | 44 (1.75) | 85 (3.3) | 4-bolt circle 1.75" diameter #10-32 tapped |

| 7T SCM with 3He Insert | 70 (2.75) | 38 (1.5); 873 (34.375) from top |

87 (3.42); 84 (3.30) after adapter to standard CCR mount |

4 bolt circle 1.06" diameter #4-40 tapped |

| 9T Horizontal Field SCM transverse or longitudinal |

28 (1.1) | 38 (1.5) | 53.3 (2.1) | 5/16"- 18 stud or tapped hole |

| 10T magnet with 1K stick | 49 (1.93) | 44 - 70 (1.73 - 2.76) 1322 mm (top flange to beam center) 1326 mm (top of O-ring to beam center) |

164 - 192 (6.45 - 7.56) 1448 mm (top flange to Bottom of well) 1452 mm (top of O-ring to Bottom of well) |

1.43" diameter copper plate 5/16"-18 threaded hole 1/4" deep |

| 11T SCM with dil fridge | 25 (0.98) top loading 48 (1.90) bottom loading |

65 (2.56) | 85.34 (3.36) top loading 250 (9.84) bottom loading with 35 mm, 0 o gap |

5/16"-18 stud 0.26" long |

| Oxford Dil fridge insert with 10T magnet Lemon | 33 (1.3) | 72 (2.83) | 90 (3.54) | 5/16-18 threaded hole,1/2" deep |

| 15T magnet 1K stick | 15 (0.59) | 82 - 134 (3.23 - 5.27) | 147 - 199 (5.79 - 7.83) | 5/16"-18 stud 0.26" long |

| 15T magnet with Oxford Dilution Fridge | 10 (0.39) | 40 (1.575) | 100 (3.94) | M6 threaded hole 10 mm deep |

| Device High Pressure |

D max. diamter mm (inches) |

B distance to beam* mm (inches) |

L max. length mm (inches) |

M mounting surface description** |

| NG7 Reflectometer 20.7MPa Heated Pressure Vessel for Thin Films |

76 (2.99) Max Wafer Diameter |

N/A | N/A | N/A |

| 400MPa Aluminum Pressure Cell in 50mm O.C. | 8 (0.31) | 89(3.51) ±25 mm 974 (38.35) from top |

45 (1.77) | 5/16"-18 stud 3/8" long |

| 400MPa Aluminum Pressure Cell in Top Loading CCR | 8 (0.31) | 1400 (55.12) from top | 45 (1.77) | 5/16"-18 stud 3/8" long |

Contacts

-

(301) 975-5295

Created June 5, 2017, Updated May 1, 2023